The phrase Emerging Trends in Chemical Manufacturing defines a revolution that is reshaping one of the world’s oldest and most influential industries. Chemical manufacturing has always been the backbone of global development—fueling pharmaceuticals, agriculture, energy, and materials science. However, in recent years, the industry has faced an unprecedented transformation driven by digitalization, sustainability, automation, and new materials innovation.

As industries aim for carbon neutrality, smart production, and global supply resilience, chemical manufacturers must adapt. This article explores the latest emerging trends that are redefining operations, productivity, and sustainability across the global chemical landscape.

1. Digital Transformation in Chemical Manufacturing

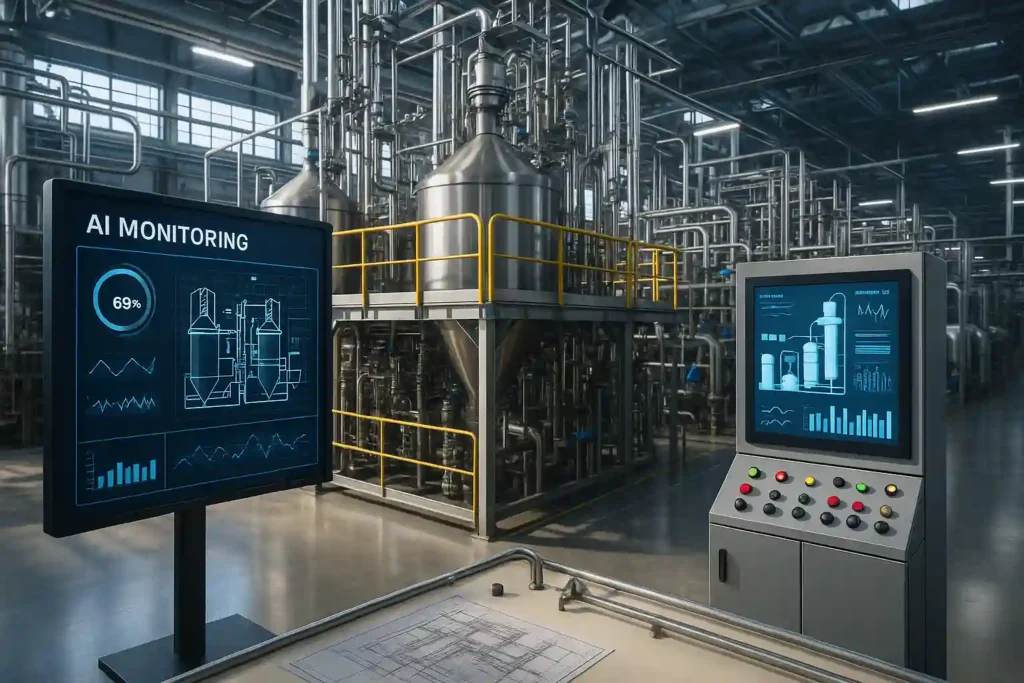

One of the most significant emerging trends in chemical manufacturing is digitalization. The integration of digital tools, smart analytics, and cloud systems has led to a new era known as Industry 4.0.

1.1 Automation and AI Integration

Modern factories now use AI-powered predictive maintenance, machine learning, and robotic automation to improve efficiency and minimize downtime.

For example:

-

Predictive sensors analyze data in real-time to prevent equipment failure.

-

AI algorithms optimize production parameters, reducing waste by up to 20%.

-

Robotic systems handle hazardous materials, ensuring workplace safety.

1.2 Digital Twins

A “digital twin” is a virtual replica of a production line or entire plant. It allows engineers to simulate operations, test new processes, and detect inefficiencies before implementing physical changes.

This reduces trial-and-error costs and enables manufacturers to experiment safely with innovative technologies.

1.3 Smart Data and Cloud Analytics

By connecting equipment through IoT (Internet of Things), manufacturers can access real-time performance dashboards.

These analytics help decision-makers monitor raw material consumption, emissions, and product quality from any location—resulting in more agile management.

2. Sustainability and Green Chemistry

Environmental responsibility has become a defining factor in emerging trends in chemical manufacturing. The industry, once associated with pollution, is now leading the charge toward sustainability.

2.1 Green Chemistry Principles

Green chemistry focuses on designing products and processes that reduce hazardous substances.

Core principles include:

-

Using renewable feedstocks

-

Minimizing waste and emissions

-

Designing biodegradable materials

-

Enhancing energy efficiency in reactions

For example, companies are shifting from fossil-based raw materials to bio-based compounds like bioethanol or bioplastics, reducing carbon footprints by 30–50%.

2.2 Circular Economy Models

Instead of the traditional “take–make–dispose” model, chemical producers are now implementing closed-loop systems.

This means that waste from one process becomes input for another—for instance, using CO₂ as a raw material for producing methanol or polymers.

Such circular strategies are vital to achieving net-zero emissions by 2050.

2.3 Energy Efficiency and Carbon Capture

Modern plants are adopting renewable energy sources such as solar thermal energy and hydrogen fuel.

Additionally, Carbon Capture, Utilization, and Storage (CCUS) technologies are helping chemical plants trap CO₂ before it’s released, converting it into valuable raw materials.

3. Advanced Materials and Nanotechnology

The development of advanced materials has become a breakthrough driver of innovation in chemical manufacturing.

3.1 Nanomaterials

Nanotechnology enables the manipulation of matter at the atomic scale to create materials with superior strength, conductivity, and chemical stability.

Applications include:

-

Nano-catalysts for faster chemical reactions

-

Self-healing coatings in automotive and aerospace industries

-

Nanoparticles for targeted drug delivery in pharmaceuticals

3.2 Smart Polymers and Bioplastics

Consumers and regulators are demanding eco-friendly alternatives to conventional plastics.

Manufacturers now produce biodegradable polymers made from corn starch, cellulose, or algae.

Smart polymers that respond to heat, light, or pH changes are revolutionizing medical devices and packaging industries.

3.3 Lightweight Composites

To meet sustainability goals in transport and construction, companies develop lightweight composites like carbon fiber-reinforced polymers (CFRP).

These materials reduce weight by 40% while maintaining strength, leading to energy savings and lower emissions.

4. Supply Chain Resilience and Localization

The COVID-19 pandemic exposed vulnerabilities in the global supply chain. As a result, emerging trends in chemical manufacturing now emphasize resilience, flexibility, and localization.

4.1 Nearshoring and Regional Hubs

Many chemical companies are relocating production closer to their customers.

This reduces dependency on international shipping and geopolitical risks.

For example, Europe and North America are investing heavily in regional chemical hubs to ensure stable access to raw materials.

4.2 Real-Time Supply Chain Visibility

Using blockchain technology and digital traceability, companies can now monitor shipments from raw material to end-user.

This transparency enhances accountability and helps prevent counterfeiting or supply disruptions.

4.3 Predictive Logistics

AI and big data enable predictive logistics, allowing manufacturers to forecast delays or price fluctuations and adapt instantly.

This results in fewer bottlenecks and optimized inventory levels.

5. Automation and Robotics Revolution

Automation is not just about replacing humans—it’s about enhancing human capability.

The adoption of collaborative robots (cobots) and autonomous guided vehicles (AGVs) is increasing across factories.

5.1 Safety and Precision

Robots handle repetitive and dangerous tasks, ensuring consistent quality while reducing workplace injuries.

Sensors and cameras enable robots to work safely alongside humans, improving both precision and throughput.

5.2 24/7 Production Capability

Unlike manual labor, robotic systems can function around the clock with minimal supervision.

This leads to improved productivity and a faster return on investment (ROI).

5.3 Workforce Transformation

While automation reduces manual labor, it creates demand for skilled roles in robotics maintenance, AI programming, and process analytics—reshaping the modern chemical workforce.

6. Artificial Intelligence and Predictive Analytics

AI is perhaps the most transformative force among emerging trends in chemical manufacturing.

It empowers factories to move from reactive to predictive operations.

6.1 Predictive Maintenance

Using AI models, sensors detect vibration, temperature, or pressure changes in machinery before failure occurs.

This minimizes downtime and extends equipment lifespan—saving millions annually.

6.2 Process Optimization

AI analyzes thousands of reaction parameters, recommending ideal conditions for yield improvement.

Chemical companies using AI-driven analytics report up to 15% increases in product quality and 10–20% reduction in energy use.

6.3 R&D Acceleration

Machine learning accelerates molecular discovery by predicting the properties of new compounds before synthesis.

This drastically reduces the time needed to develop new materials, catalysts, or drugs.

7. Global Regulatory Changes and Compliance

Another key area in emerging trends in chemical manufacturing is the shift toward stricter global regulations.

7.1 Safety Standards

Governments now require detailed Material Safety Data Sheets (MSDS), hazard labeling under GHS, and compliance with frameworks like REACH (EU) and TSCA (US).

7.2 Sustainable Production Certifications

Chemical manufacturers are adopting certifications such as ISO 14001 (Environmental Management) and Responsible Care® to demonstrate ethical production.

7.3 Trade and Supply Regulations

As supply chains diversify, companies must navigate new customs, tariffs, and export control measures—requiring strong compliance management systems.

8. The Rise of Bio-Manufacturing and Biotechnology

Biotechnology is becoming a central pillar of chemical manufacturing innovation.

8.1 Enzyme-Based Reactions

Instead of harsh catalysts, enzymes are now used to perform chemical transformations at lower temperatures, reducing energy consumption.

8.2 Microbial and Algae-Based Production

Microbes and algae are engineered to produce valuable chemicals such as biofuels, amino acids, and bioplastics—turning biological systems into “mini factories.”

8.3 Pharmaceutical and Food Applications

Bio-manufacturing enables safer, cleaner production of vitamins, food additives, and active pharmaceutical ingredients (APIs).

9. Challenges Facing Chemical Manufacturers

Despite these advancements, the industry faces ongoing challenges.

9.1 Cost of Transition

Implementing smart technologies, automation, and green processes requires heavy investment, making it harder for small and mid-sized manufacturers to compete.

9.2 Talent Shortages

A lack of skilled labor in digital fields—like AI, robotics, and data science—limits innovation adoption.

9.3 Global Competition

Countries such as China, the US, and Germany dominate innovation spending. Smaller economies must collaborate or specialize to remain competitive.

10. The Future Outlook

The future of chemical manufacturing will be intelligent, circular, and data-driven.

As sustainability becomes a legal and moral obligation, and technology continues to evolve, manufacturers will rely on automation, AI, and bio-based chemistry to stay ahead.

What We Can Expect by 2030

-

Over 70% of plants using predictive AI and IoT systems

-

50% reduction in CO₂ emissions through green energy

-

Widespread adoption of digital twins and blockchain logistics

-

Expanded biomanufacturing for renewable materials and fuels

Frequently Asked Questions (FAQs)

1. What are the main emerging trends in chemical manufacturing?

Key trends include digitalization, sustainability, nanotechnology, bio-manufacturing, and AI-driven process optimization.

2. How is green chemistry changing the industry?

Green chemistry promotes renewable feedstocks, waste reduction, and safer production—creating eco-friendly alternatives to traditional materials.

3. Why is digital transformation important for chemical manufacturers?

It enhances productivity, improves safety, reduces costs, and allows real-time decision-making through automation and data analytics.

4. What role does biotechnology play in chemical manufacturing?

Biotechnology enables eco-efficient production using enzymes, microbes, and renewable biological sources to replace petrochemicals.

5. What challenges do manufacturers face when adopting new technologies?

High implementation costs, training needs, and complex regulatory requirements remain the biggest barriers to transformation.

Conclusion

The Emerging Trends in Chemical Manufacturing are not simply technological changes—they represent a paradigm shift toward smarter, greener, and more sustainable industry practices.

From AI-driven analytics and nanotechnology to bio-manufacturing and circular economies, every innovation is pushing the boundaries of efficiency and environmental responsibility.

Manufacturers who adapt early will not only gain a competitive edge but will also shape a cleaner and more intelligent industrial future.

🌍 Call to Action:

Stay ahead of the curve—partner with forward-thinking suppliers like BIC Company to embrace digital innovation, sustainability, and global excellence in chemical manufacturing.