BIC LUBRICANT

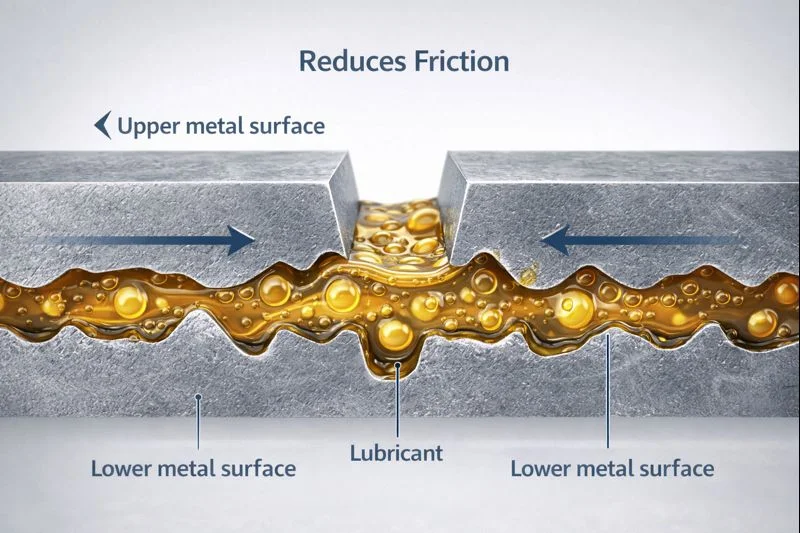

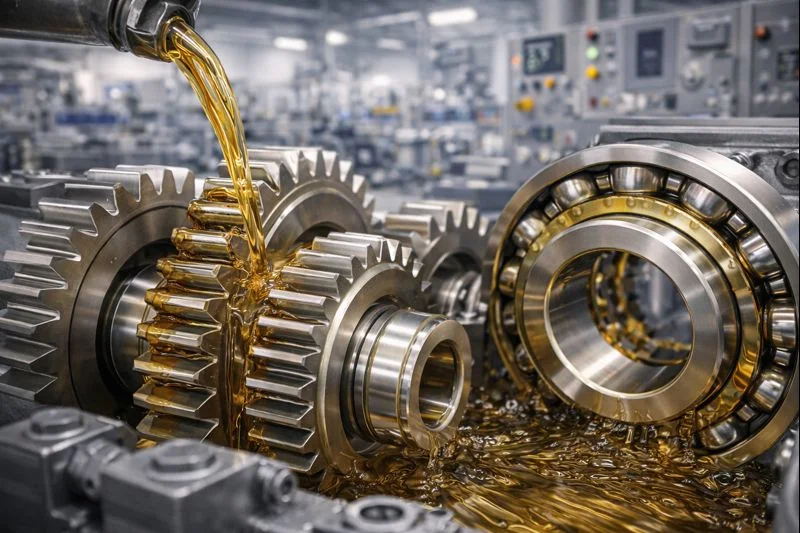

The BIC Lubricant category represents a specialized range of lubrication solutions developed to support industrial performance, mechanical efficiency, and equipment longevity. Lubricants play a critical role in reducing friction, minimizing wear, controlling temperature, and protecting components operating under various loads and environmental conditions. This category is structured to meet the needs of industrial, commercial, and technical sectors that rely on consistent and reliable lubrication systems.

Unlike single-product listings, the BIC Lubricant category provides a comprehensive overview of lubrication solutions designed for different mechanical systems, operating environments, and performance requirements. These lubricants are formulated to support smooth operation, reduce energy consumption, and extend the service life of machinery and components.

The category focuses on performance-driven lubrication rather than generic oil solutions, making it suitable for industries that demand precision, durability, and operational stability.

Understanding the Role of Lubricants in Industrial Systems

Lubricants are essential materials used to control friction and wear between moving surfaces. In industrial environments, inadequate lubrication can lead to excessive heat, component failure, increased downtime, and high maintenance costs. Proper lubrication directly impacts productivity, safety, and long-term equipment reliability.

The BIC Lubricant category addresses these challenges by offering lubrication solutions designed to perform under demanding conditions such as:

-

High mechanical loads

-

Continuous or high-speed operation

-

Extreme temperatures

-

Exposure to moisture, dust, or chemicals

By focusing on engineered lubricant formulations, this category supports efficient mechanical performance while protecting critical components from premature failure.

Scope of the BIC Lubricant Category

The BIC Lubricant category is designed to cover a broad spectrum of lubrication needs across multiple industries. Rather than focusing on a single lubricant type, the category includes solutions developed for different applications, equipment types, and operating environments.

This category typically covers:

-

Industrial lubricants for machinery and mechanical systems

-

Specialized lubricants for high-load and high-temperature applications

-

Lubrication solutions for moving parts, bearings, and joints

-

Protective lubricants designed to reduce corrosion and wear

By organizing lubrication solutions under one category, users can evaluate options based on performance characteristics, application requirements, and operational conditions rather than brand-specific or isolated product descriptions.

Industrial and Commercial Applications

The versatility of the BIC Lubricant category makes it suitable for a wide range of industrial and commercial applications. Lubricants are a foundational element in many mechanical systems, and their quality directly affects operational efficiency.

Common application areas include:

-

Manufacturing equipment and production lines

-

Automotive and transportation systems

-

Industrial machinery and heavy equipment

-

Power generation and mechanical assemblies

-

Construction and infrastructure-related machinery

Each application requires lubrication solutions that perform reliably under specific stress factors, making category-based selection critical for optimal results.

Performance Expectations and Quality Focus

The BIC Lubricant category emphasizes consistent quality and performance stability. Lubricants within this category are formulated to maintain their properties over time, even under continuous operation and challenging conditions.

Key performance considerations include:

-

Friction reduction and wear protection

-

Thermal stability and heat resistance

-

Oxidation resistance and long service intervals

-

Protection against corrosion and contamination

By prioritizing performance-focused lubrication, this category supports industries seeking to improve equipment reliability, reduce maintenance frequency, and enhance overall operational efficiency.

Choosing products from the BIC Lubricant category means selecting lubrication solutions designed to support mechanical efficiency, operational stability, and long-term equipment performance. This category is structured for industrial buyers, maintenance teams, engineers, and technical decision-makers who require dependable lubrication across different systems and operating conditions.

Rather than focusing on individual lubricant products, this category allows buyers to explore lubrication solutions based on functional needs such as friction control, load resistance, temperature tolerance, and environmental exposure. The BIC Lubricant category supports informed selection by grouping solutions according to performance characteristics and application demands.

Buyers benefit from this category by gaining access to:

-

Lubrication solutions suitable for diverse mechanical systems

-

Materials engineered for continuous and heavy-duty operation

-

Options designed to improve equipment reliability and uptime

-

A structured approach to selecting the right lubricant for specific applications

This category is ideal for operations that prioritize performance consistency, reduced wear, and efficient maintenance planning.

Affordable Price BIC Lubricant

Cost management is a critical factor in lubrication strategy. The BIC Lubricant category is designed to deliver high performance while maintaining competitive and reasonable pricing. Effective lubrication reduces energy losses, minimizes wear-related failures, and extends maintenance intervals, all of which contribute to lower total operating costs.

Rather than focusing solely on initial purchase price, this category emphasizes value over time. High-quality lubricants help reduce downtime, limit component replacement, and improve overall system efficiency, resulting in measurable long-term savings.

Key pricing advantages of the BIC Lubricant category include:

-

Reduced maintenance frequency due to stable lubricant performance

-

Lower risk of mechanical damage and premature component failure

-

Optimized formulations that support efficient lubricant consumption

-

Scalable solutions for small operations and large industrial facilities

This balanced pricing approach makes the category suitable for both cost-sensitive operations and performance-driven industrial environments.

Features

The BIC Lubricant category is defined by a set of performance-focused features that address the demands of modern mechanical systems. These features are designed to support reliability, efficiency, and long-term equipment protection.

Core category features include:

-

Engineered lubricant formulations for friction and wear reduction

-

Stability under varying temperatures and operating conditions

-

Compatibility with a wide range of mechanical components

-

Protection against corrosion, oxidation, and contamination

These features ensure that the category meets the requirements of industries where lubrication quality directly impacts productivity and equipment lifespan.

Pros and Cons

Pros

The BIC Lubricant category offers several key advantages:

-

Broad application coverage across multiple industries

-

Improved mechanical efficiency and reduced energy loss

-

Enhanced protection for critical moving components

-

Support for extended service intervals and reduced downtime

Cons

Considerations when selecting from this category include:

-

Proper lubricant selection requires understanding operating conditions

-

Over-specification may not be necessary for low-demand applications

Evaluating these factors helps ensure optimal lubricant selection based on real operational needs.

Conclusion

The BIC Lubricant category provides a comprehensive solution for industries that depend on effective lubrication to maintain mechanical reliability and operational efficiency. By focusing on engineered formulations and performance consistency, this category supports long-term equipment protection and optimized maintenance strategies.

Its balanced approach to performance, cost efficiency, and application versatility makes it a valuable category for businesses seeking dependable lubrication solutions rather than short-term fixes.

Frequently Asked Questions

What types of applications does the BIC Lubricant category cover?

The BIC Lubricant category covers a wide range of industrial, mechanical, and commercial applications where friction reduction, wear protection, and performance stability are required.

Why is category-based lubricant selection important?

Selecting lubricants at the category level helps users compare solutions based on performance requirements, operating conditions, and system compatibility rather than focusing on individual products.

Are BIC Lubricant solutions suitable for continuous operation systems?

Yes. The category includes lubrication solutions designed to perform reliably under continuous operation, high loads, and demanding industrial environments.

How do lubricants from this category help reduce maintenance costs?

By minimizing friction, reducing wear, and protecting components from corrosion, these lubricants extend service intervals and reduce unexpected equipment failures.

Can BIC Lubricant solutions be used across different industries?

Yes. The category supports multiple industries including manufacturing, automotive, construction, and heavy machinery, depending on operational requirements.

Showing all 5 results