BIC POLYMER & compound

The BIC Polymer & Compound category represents a specialized segment within the polymer industry, focusing on engineered polymer materials and custom compound solutions designed for industrial, commercial, and technical applications. This category is dedicated to advanced polymer technologies that enhance material performance, durability, flexibility, and resistance under various environmental and mechanical conditions.

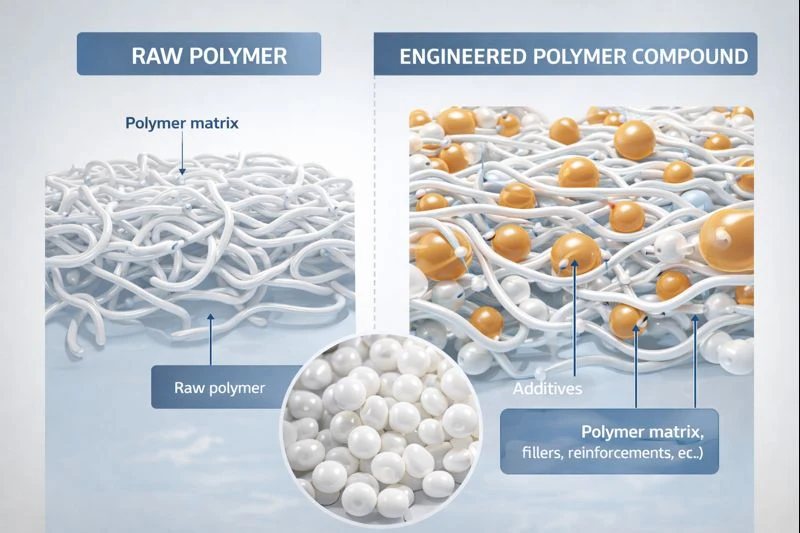

Polymers and compounds play a critical role in modern manufacturing across industries such as automotive, construction, electronics, packaging, medical devices, and consumer goods. By combining base polymers with specific additives, fillers, reinforcements, or modifiers, polymer compounds are engineered to meet precise functional requirements that standard raw polymers cannot achieve on their own.

The BIC Polymer & Compound category is structured to provide reliable, high-quality polymer solutions that support both mass production and specialized industrial projects. This category is not limited to a single polymer type; instead, it encompasses a wide range of thermoplastics, thermosets, elastomers, and performance compounds tailored for diverse technical needs.

Understanding Polymers and Compounds in Industrial Applications

Polymers are long-chain molecular materials known for their versatility, lightweight nature, and adaptability. However, in many industrial environments, raw polymers alone are insufficient. This is where polymer compounds become essential.

Polymer compounds are created by blending base polymers with additives such as stabilizers, colorants, flame retardants, impact modifiers, lubricants, and reinforcing agents like glass fiber or mineral fillers. These modifications allow manufacturers to fine-tune physical, thermal, electrical, and chemical properties.

Within the BIC Polymer & Compound category, materials are developed to address challenges such as:

-

Mechanical stress and repeated loading

-

Exposure to heat, chemicals, or UV radiation

-

Dimensional stability under varying temperatures

-

Electrical insulation or conductivity requirements

-

Aesthetic consistency and surface quality

By offering compound-based solutions, this category supports industries that require consistent performance, compliance with technical standards, and long-term reliability.

Scope of the BIC Polymer & Compound Category

The BIC Polymer & Compound category is designed to serve as a comprehensive resource for polymer-based materials and solutions. Rather than focusing on individual items, this category provides access to a structured range of polymer compounds that can be adapted to multiple use cases.

This category typically includes:

-

Engineering polymer compounds for structural components

-

Modified thermoplastics for injection molding and extrusion

-

Impact-resistant and reinforced polymer blends

-

Heat-stabilized and flame-retardant compounds

-

Customized color and performance compounds

Each segment within this category addresses specific industrial demands, allowing engineers, manufacturers, and procurement specialists to select materials that align with their production goals and regulatory requirements.

Applications Across Multiple Industries

The versatility of the BIC Polymer & Compound category makes it relevant across a wide spectrum of industries. Polymer compounds are not limited to one sector; instead, they form the backbone of many modern manufacturing processes.

In the automotive industry, polymer compounds are used to reduce weight while maintaining strength and safety. In construction, they contribute to insulation, durability, and resistance to environmental factors. In electronics, polymers provide electrical insulation, thermal stability, and precise dimensional control.

Other common application areas include:

-

Industrial machinery components

-

Packaging materials with enhanced barrier properties

-

Consumer products requiring durability and aesthetic quality

-

Medical and healthcare components requiring controlled material behavior

This broad application range makes the category essential for businesses seeking adaptable material solutions rather than single-purpose products.

Material Performance and Quality Standards

Quality and consistency are critical in polymer and compound selection. The BIC Polymer & Compound category emphasizes materials that meet industry-recognized standards and performance benchmarks. Consistency in formulation ensures predictable behavior during processing and end-use performance.

Key performance factors considered within this category include:

-

Mechanical strength and impact resistance

-

Thermal performance and heat deflection temperature

-

Chemical and environmental resistance

-

Processability for molding and extrusion techniques

-

Long-term aging and durability

By prioritizing engineered compounds over generic materials, this category supports manufacturers in reducing production risks, minimizing defects, and maintaining product quality at scale.

Buy BIC Polymer & Compound

Purchasing materials from the BIC Polymer & Compound category means gaining access to a comprehensive range of engineered polymer solutions designed for industrial reliability and performance consistency. This category is structured to support manufacturers, suppliers, and project-based buyers who require dependable polymer compounds for various production processes.

Unlike single-product pages, this category enables buyers to explore a wide selection of polymer compounds based on performance characteristics, processing methods, and application requirements. Whether the goal is to improve mechanical strength, enhance thermal stability, or achieve specific aesthetic properties, the BIC Polymer & Compound category offers flexible material options suited for both standardized and customized applications.

Buyers selecting from this category benefit from:

-

A structured overview of compound-based polymer solutions

-

Materials suitable for injection molding, extrusion, and industrial forming

-

Compatibility with modern manufacturing standards and processes

-

Reliable sourcing for long-term production planning

This category is ideal for decision-makers who prioritize performance-driven material selection rather than off-the-shelf polymer resins.

Affordable Price BIC Polymer & Compound

Cost efficiency is a key factor in industrial material selection. The BIC Polymer & Compound category is designed to balance material performance with competitive pricing, allowing businesses to optimize production costs without compromising on quality.

By offering polymer compounds that reduce processing challenges, waste, and defect rates, this category contributes to overall cost savings throughout the manufacturing cycle. Engineered compounds often lower long-term expenses by improving durability, extending product lifespan, and minimizing maintenance or replacement needs.

The pricing structure within this category reflects:

-

Optimized material formulations for efficient processing

-

Reduced need for secondary treatments or reinforcements

-

Scalable solutions for both small and large production volumes

-

Consistent quality that minimizes production variability

As a result, the BIC Polymer & Compound category supports sustainable cost management while meeting technical and operational demands.

Features

The BIC Polymer & Compound category is defined by a set of core features that distinguish it from generic polymer material offerings. These features are focused on performance customization, process reliability, and application versatility.

Key category features include:

-

Engineered polymer compounds with tailored mechanical and thermal properties

-

Compatibility with diverse industrial processing methods

-

Enhanced resistance to environmental, chemical, and mechanical stress

-

Consistent material quality across production batches

These features make the category suitable for industries that require precision, repeatability, and adaptability in material performance.

Pros and Cons

Pros

The BIC Polymer & Compound category offers several advantages for industrial users:

-

Broad range of engineered polymer solutions for multiple industries

-

Improved performance compared to unmodified base polymers

-

Enhanced durability and reliability in demanding environments

-

Reduced production risks through consistent material behavior

Cons

While highly versatile, there are considerations to keep in mind:

-

Compound selection requires technical evaluation for optimal results

-

Over-engineered materials may not be necessary for low-demand applications

Understanding these pros and cons helps buyers make informed decisions when selecting materials from this category.

Conclusion

The BIC Polymer & Compound category serves as a strategic resource for industries that depend on high-performance polymer materials. By focusing on engineered compounds rather than raw polymers, this category addresses the growing demand for materials that deliver reliability, efficiency, and adaptability.

Its broad application scope, balanced pricing, and performance-driven structure make it an essential category for manufacturers seeking long-term material solutions rather than short-term fixes. The category is designed to support innovation, scalability, and consistent production outcomes across diverse industrial sectors.

Frequently Asked Questions

What is included in the BIC Polymer & Compound category?

This category includes a wide range of engineered polymer compounds designed to enhance mechanical, thermal, and chemical performance for industrial applications.

Who should choose polymer compounds instead of base polymers?

Manufacturers and project-based buyers who require consistent performance, improved durability, and optimized processing efficiency benefit most from polymer compounds.

Are BIC Polymer & Compound materials suitable for mass production?

Yes. The materials in this category are designed for scalable manufacturing processes, ensuring stable quality across high-volume production.

Can these compounds be used in different processing methods?

The category supports various processing techniques such as injection molding, extrusion, and industrial forming, depending on compound formulation.

How do polymer compounds help reduce production costs?

By improving processing stability, reducing defects, and enhancing product lifespan, polymer compounds lower overall operational and maintenance costs.

Showing all 4 results