BIC TECTILE PRODUCT

BIC TECTILE PRODUCT

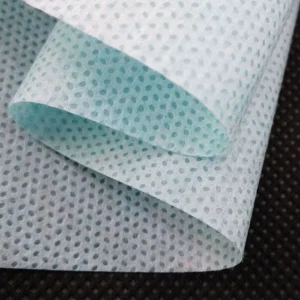

BIC Tectile Products represent a specialized category of high-performance nonwoven textile materials designed for industrial, medical, hygiene, and promotional applications. These products are manufactured using advanced production technologies to ensure durability, consistency, and adaptability across a wide range of industries.

As global demand for functional textiles continues to grow, BIC Tectile Products have positioned themselves as reliable solutions for businesses seeking quality, scalability, and customization. From filtration and medical use to promotional and technical applications, these textile materials offer both performance and flexibility.

What Are BIC Tectile Products?

BIC Tectile Products are nonwoven textile materials engineered to deliver specific functional properties such as breathability, strength, softness, and resistance. Unlike traditional woven fabrics, nonwoven textiles are produced by bonding fibers together through mechanical, thermal, or chemical processes.

This production method allows for:

-

Cost-effective manufacturing

-

Consistent material structure

-

Customizable thickness, weight, and texture

-

Compatibility with modern printing and finishing techniques

BIC Tectile Products are widely used in sectors where performance, hygiene, and efficiency are critical.

Types of BIC Tectile Products

Meltblown Nonwoven Fabric

Meltblown fabric is one of the most important BIC Tectile Products, known for its ultra-fine fiber structure and excellent filtration properties. This material is produced by melting polymer resin and extruding it through fine nozzles using high-speed hot air.

Key Features:

-

High filtration efficiency

-

Lightweight and breathable

-

Excellent particle capture

-

Ideal for medical and industrial filtration

Common Applications:

-

Medical masks and respirators

-

Air and liquid filtration systems

-

Protective medical textiles

Spunbond Nonwoven Fabric

Spunbond fabric is another core product within the BIC Tectile Product category. It is produced by spinning continuous filaments and bonding them together to form a strong, uniform fabric.

Key Features:

-

High tensile strength

-

Durable and tear-resistant

-

Lightweight yet stable

-

Cost-efficient for mass production

Common Applications:

-

Medical gowns and covers

-

Packaging materials

-

Promotional and industrial textiles

Advantages of BIC Tectile Products

BIC Tectile Products offer several advantages that make them suitable for both industrial-scale manufacturing and specialized applications.

High Quality and Consistency

Each BIC Tectile Product is manufactured under strict quality control standards to ensure uniformity in weight, texture, and performance. This consistency is essential for industries that rely on predictable material behavior.

Customization Options

BIC Tectile Products can be customized based on:

-

GSM (grams per square meter)

-

Color

-

Thickness

-

Surface texture

-

Printing compatibility

This level of customization allows brands and manufacturers to tailor materials to their exact needs.

Eco-Friendly Manufacturing

Many BIC Tectile Products are designed with sustainability in mind. Nonwoven textiles often require less water and energy compared to traditional textile manufacturing processes, making them a more environmentally responsible choice.

Industrial Applications of BIC Tectile Products

BIC Tectile Products are widely used across multiple industries due to their versatility and functional performance.

Medical and Healthcare Industry

Nonwoven textiles play a critical role in healthcare environments where hygiene and safety are paramount. BIC Tectile Products are used in:

-

Surgical masks

-

Medical drapes

-

Disposable gowns

-

Protective covers

Their breathable yet protective structure helps maintain comfort while ensuring safety.

Promotional and Advertising Applications

BIC Tectile Products are increasingly used in the promotional and advertising industry due to their flexibility, printability, and professional appearance. Brands looking to create long-lasting promotional materials benefit greatly from nonwoven textile solutions.

These products are ideal for:

-

Promotional bags and covers

-

Branded protective textiles

-

Exhibition and event materials

-

Corporate giveaways

Their smooth surface and structural stability allow high-quality printing, ensuring that logos, slogans, and brand elements remain sharp and durable.

Printing Compatibility of BIC Tectile Products

One of the major advantages of BIC Tectile Products is their compatibility with modern printing technologies. This makes them a strong choice for businesses focused on customization and branding.

DTF Printing on Nonwoven Textiles

Direct to Film (DTF) printing is widely used for applying vibrant and durable designs onto textile surfaces. BIC Tectile Products provide an excellent base for DTF printing due to their:

-

Stable surface structure

-

Absorption control

-

Heat resistance

DTF printing allows full-color designs, gradients, and detailed graphics to be transferred effectively onto nonwoven materials, making it ideal for promotional textiles.

UV DTF Printing for Hybrid Applications

While DTF printing is primarily used for textile surfaces, UV DTF printing expands branding possibilities by enabling high-quality printing on rigid and semi-rigid surfaces. Businesses often combine printed BIC Tectile Products with UV DTF printed components to create cohesive branding solutions across multiple materials.

This hybrid approach enhances brand visibility and consistency in promotional campaigns.

Technical and Industrial Use Cases

Beyond promotional and medical applications, BIC Tectile Products are also widely used in technical and industrial sectors.

Filtration Systems

Meltblown nonwoven fabrics are essential components in air and liquid filtration systems. Their micro-fiber structure allows efficient particle capture while maintaining airflow.

Agriculture and Construction

Spunbond fabrics are used in agriculture for crop protection and soil stabilization. In construction, they serve as protective layers, insulation components, and dust barriers.

Packaging and Protection

Nonwoven textiles are commonly used for protective packaging due to their lightweight nature and resistance to tearing.

Durability and Performance

BIC Tectile Products are engineered to maintain performance under various conditions. Their durability makes them suitable for both disposable and semi-durable applications.

Key performance characteristics include:

-

Resistance to moisture

-

Breathability

-

Structural stability

-

Adaptability to different environments

These qualities ensure reliability across a wide range of uses.

Why Choose BIC Tectile Products?

Choosing BIC Tectile Products means investing in materials that deliver value, quality, and adaptability.

Reliable Manufacturing Standards

BIC maintains high production standards to ensure that every textile product meets industry expectations.

Wide Range of Applications

From healthcare and filtration to advertising and packaging, BIC Tectile Products offer unmatched versatility.

Branding and Customization Potential

The ability to combine textile printing methods such as DTF with complementary techniques like UV DTF makes these products ideal for integrated branding strategies.

Sustainability and Future of Nonwoven Textiles

Sustainability has become a key factor in modern textile production, and BIC Tectile Products align well with this global shift. Nonwoven manufacturing processes generally consume less water and energy compared to traditional textile weaving, reducing environmental impact.

Many BIC Tectile Products are designed to be recyclable and disposable in an environmentally responsible manner. This makes them suitable for industries seeking to balance performance with sustainability goals.

As demand for hygienic, lightweight, and customizable materials continues to rise, nonwoven textiles are expected to play an even more significant role in future industrial and promotional applications.

Quality Control and Manufacturing Excellence

BIC Tectile Products are manufactured under strict quality control protocols to ensure reliability and consistency. Each production stage is carefully monitored to maintain:

-

Uniform fiber distribution

-

Consistent thickness and density

-

Reliable performance in end-use applications

This attention to detail allows businesses to confidently integrate BIC Tectile Products into their supply chains.

Conclusion

BIC Tectile Products offer a comprehensive solution for industries seeking high-quality nonwoven textile materials. With applications ranging from medical and filtration to advertising and industrial use, these products deliver versatility, durability, and excellent print compatibility.

Their ability to support modern printing techniques such as DTF printing, along with complementary branding methods like UV DTF printing, makes them an ideal choice for businesses focused on customization and brand visibility.

By choosing BIC Tectile Products, companies gain access to innovative textile solutions designed to meet today’s performance, sustainability, and branding demands.

Showing all 2 results